P2767 Input speed sensor 2 circuit no signal

When monitored this DTC the Engine speed than 450 rpm with none of the following DTCs present : engine speed, TCM undervoltage, output speed sensor, and or rear wheel speed DTCs. Also required are all wheel speeds above 250 RPM and no wheel slip detected signal from ABS system. Set condition this DTC the Input speed 2 (N3) signal is equal to 0 rpm

Possible causes P2767 code:

- Sensor supply circuit open

- Input speed 2 N3 Signal circuit open

- Input speed 2 N3 Signal circuit shorted to another circuit

- Input speed 2 N3 Signal circuit shorted to ground

- Speed sensor ground circuit shorted to another circuit

- Speed sensor ground circuit shorted to ground

- Input speed sensor 2 (N3)

- Transmission control module (TCM)

Diagnostic test P2767 code

Step 1. Check if DTC is current

Note : The transmission control module stores under environmental data the transmission operating conditions when the DTC was set. Before erasure of any DTC, record all information pertaining to the DTC, even if there is more than one DTC stored.

With the scan tool, erase transmission DTCs. Using the environmental data previously recorded, drive the vehicle and try to duplicate the conditions in which the DTC originally set.

Did the DTC P2767 reset ?

Yes, go to step 2.

No, go to step 10.

Step 2. Check the sensor supply voltage circuit for an open

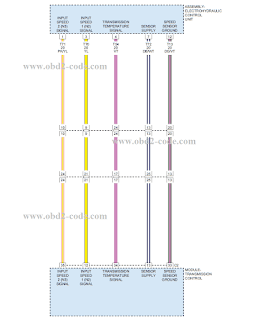

Turn the ignition off to the lock position. Disconnet the TCM C2 harness connector. Disconnect the electrohydraulic control unit assembly harness connector.

Note : Check connectors clean/repair as necessary.

Measure the resistance of the sensor supply circuit from the TCM C2 harness connector to the electrohydraulic control unit assembly harness connector.

Is the resistance above 5.0 Ohms ?

Yes, repair the sensor supply circuit for an open.

No, go to step 3.

Step 3. Check the Input speed 2 N3 signal circuit for an open

Measure the resistance of the input speed 2 N3 signal circuit from the TCM C2 harness connector to the electrohydraulic control unit assembly harness connector.

Is the resistance above 5.0 Ohms ?

Yes, repair the input speed 2 N3 signal circuit for an open.

No, go to step 4.

Step 4. Check the T13 sensor ground circuit for an open

Measure the resistance of the sensor ground circuit from the TCM C2 harness connector to the electrohydraulic control assembly harness connector.

Is the resistance above 5.0hms ?

Yes, repair the sensor ground circuit for an open.

No, go to step 5.

Step 5. Check the input speed 2 N3 signal circuit for a short to another circuits

Measure the resistance of the Input speed 2 N3 signal circuit to all the other circuit in the electrohidraulic control unit assembly harness connectors.

Is the resistance below 5.0 between the input speed 2 N3 signal sircuit and any other circuit(s) in the electrohydraulic control unit assembly harness connector ?

Yes, repair the input speed 2 N3 signal circuit for a short to another circuits.

No, go to step 6.

Step 6. Check the input speed 2 N3 signal circuit for a short to ground

Measure the resistance between ground an the input speed 2 N3 signal circuit.

Is the resistance below 5.0 Ohm?

Yes, repair the Input speed 2 N3 Signal circuit for a short ground. Perform the transmission test.

No, go to step 7.

Step 7. Check the sensor ground circuit for a short to another circuits

Measure the resistance between the sensor ground circuit to all the other circuits in the electrohydraulic control unit assembly harness connector.

Is the resistance below 5.0 ohms between the sensor ground circuit and any other circuits in the electrohydraulic control unit assembly harness connector?

Yes, repair the sensor ground circuit for a short to another circuits.

No, go to step 8.

Step 8. Check the sensor ground circuit for a short to ground

Is the resistance below 5.0 Ohms?

Yes, repair the sensor ground circuit for a short to ground.

No, go to step 9.

Step 9. Check the input speed 2 N3 signal

Reconnect the electrohydraulic control unit assembly harness connector. Using lab scope, backprobe the Input speed 2 N3 signal circuit at the TCM C2 harness connector.

Properly support the vehicle.

Raise all drive wheels off the ground. Start the engine.

Warning : To avoid possible serious or fatal injury, keep hands and feet clear of rotating wheels.

Place gear selector in drive and increase vehicle speed to engage 2nd gear. Compare the scope pattern on the lab scope with a typical 5 volt square wave pattern.

Is the scope patterencomparable to the typical 5 volt square wave signal scope pattern ?

Yes, using the schematics as a guide, check the transmission control module (TCM) terminals for corrosio, damage, or terminal push out. Pay particular attention to all power and ground circuits. If no problems are found, replace the TCM. Perform NAG1 Transmission Verification Test.

No, replace the input speed sensor 2 N3 in accordance with the service information. Perform the transmission verification test.

Step 10. Check the wiring and connectors

The condition necessary to set this DTC are not present at this time. Using the schematics as a guide, inspect the wiring and connectors specific to this circuit. Wiggle the wiring and connectors while cheking for any possible open or shorted circuits. Check for any service information tune-ups or technical service bulletins that may apply.

Were there any problems found ?

Yes, repair as necessary.

No, test complete.

0 Response to "P2767 Input speed sensor 2 circuit no signal"

Post a Comment