P1731 Incorrect gear engaged

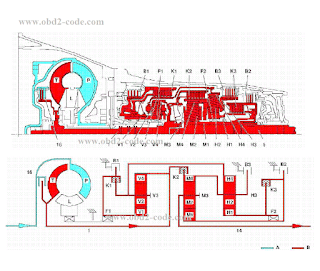

P1731 code - The transmission control module (TCM) constanty calculates the transmission ratio based on the input speed sensor 1 and 2 (N2-N3) signals and the calculated output shaft speed. The intent of this diagnostics to detect if the transmission is trying to mechanically shift into a different gear than the TCM intends.

Note : The transmission control module is programmed to immediately place the transmission into neutral if P0730 or P1731 codes are set. These codes indicate that the transmission experienced unknown or incorrect gear ratio. Placing the transmission in neutral prevents potential catastrophic failure. When this occurs, the transmission will remain in neutral until the vehicle slow to 29 Km/h (18 mph).

When monitored this DTC the Engine rpm grater than 450 rpm, no N2 - N3 input speed sensor error present, no gear selector lever errors present, no ABS system errors, and vehicle speed above 10 Km/h (6 mph). Set condition this DTC no shifting operation and actual gear differs from the target gear. No shifting operation actual (calculated) gear differs from target (expected) gear, actual (calculated) turbine speed is greater than 300 rpm or calculated transmission ratio is above threshold. During an upshift actual (calculated) gear is less than target (expected) gear. During downshift actual (calculated) gear is greater than target (expected) gear. Exception : Actual (calculated) gear is 1st and target (desired) gear is 2nd.

Possible causes P1731 code :

- Low fluid level

- ABS DTCs present

- Transmission solenoid, speed sensor and or other electrical related DTCs present

- Intermittent sticking valve in the valve body

- Internal transmission problem

- Transmission control module (TCM)

Diagnostic test P1731 code

Step 1. Check if ABS DTCs are present

With the scan tool, check for ABS DTCs.

Are there any ABS DTCs present ?

Yes, refer to antilock brake system (ABS) diagnosis and testing and perform the appropriate diagnostic procedure.

No, go to step 2.

Step 2. Check if transmission solenoid DTCs are present

With the scan tool, check for other transmission DTCs.

Are there any transmission solenoid, speed sensor and/or any other transmission electrical related DTCs present?

Yes, refer to Transmission control Module (TCM) diagnosis and testing and perform the appropriate diagnostic procedure.

No, go to step 3.

Step 3. Check transmission fluid level

Note: Low fluid level can be the cause of many transmission problems. Visually inspect the transmission and cooler lines for leakage and repair as necessary and adjust the fluid level in accordance with the service information. If no visual leaks are observed and the vehicle has obtained over 1610 km (1000 miles) from either new or transmission service, a fluid level check is unnecessary.

Check the transmission fluid level and condition in accordance with the service information.

Is the fluid level correct?

Yes, go to step 4.

No, correct the fluid level in accordance with the service information. Refer to transmission and transfer case/automatic NAG1 fluid and filter - standard procedure. Perform NAG1 Transmission Verification Test.

Step 4. Check environmental data

With the scan tool, check environmental data for P1731

Did environmental data show the code settting during a 3-4 upshift or 4-3 downshift ?

Yes, note : debris may enter trhough the vents in the top of the valvebody. The debris can be a very small sliver that is visibly unnoticable unless flushing onto a fine filter paper. The debris has the potential to stick the 3-4 shift pressure or 3-4 holding valves. If either valve is stuck during a 3-4 upshift or 4-3 downshift, a shift flare, bump shift, harsh shift, or neutraling out will occur.

Flush and clean the valve body in accordance with the service information. Refer to transmission and transfer case/automatic - NAG1/UNIT, electrohydraulic control - cleaning. Pay particular attention to the 3-4 shift pressure and 3-4 holding valve. Perform NAG1 Transmission Verification Test.

No, go to step 5.

Step 5. Check for internal transmission problem

Check for an internal transmission mechanical problems. Remove the transmission oil pan and inspect for excessive debris or a plugged transmission oil filter. Refer to transmission and transfer case/automatic NAG1/FLUID and FILTER standar procedure. Inspect the valve body for foreign material, starting with the four valves associated with the shift described in the environmental data (shift pressure, holding, overlap, command), and continue on to the other valves.

This DTC is usually set due to an internal transmission problem such as but not limited to stuck solenoid valve and or contamination in the valve body, broken springs, leaking clutch seals, dislodged or broken snap ring etc. Inspect the internal transmission.

Were there any problems found ?

Yes, repair as necessary in accordance with the service information. Perform NAG1 Transmission Verification Test.

No, using the schematics as a guide, check the transmission control module pins, terminals, and connectors for corrosion, damage, or terminal push out. Pay particular attention to all power and ground circuit. If no problems are found, replace and programmed the TCM in accordance with the service information. Perform NAG1 Transmission Verification Test.

0 Response to "P1731 Incorrect gear engaged"

Post a Comment